BISAN sure’n safe® Chemical Dosing System

Our sure’n safe® Chemical Dosing Systems are designed for sure chemical delivery and safe operation. With several options and adders, sure’n safe® systems can meet all your chemical dosing needs and requirements.

Check out our brochure here.

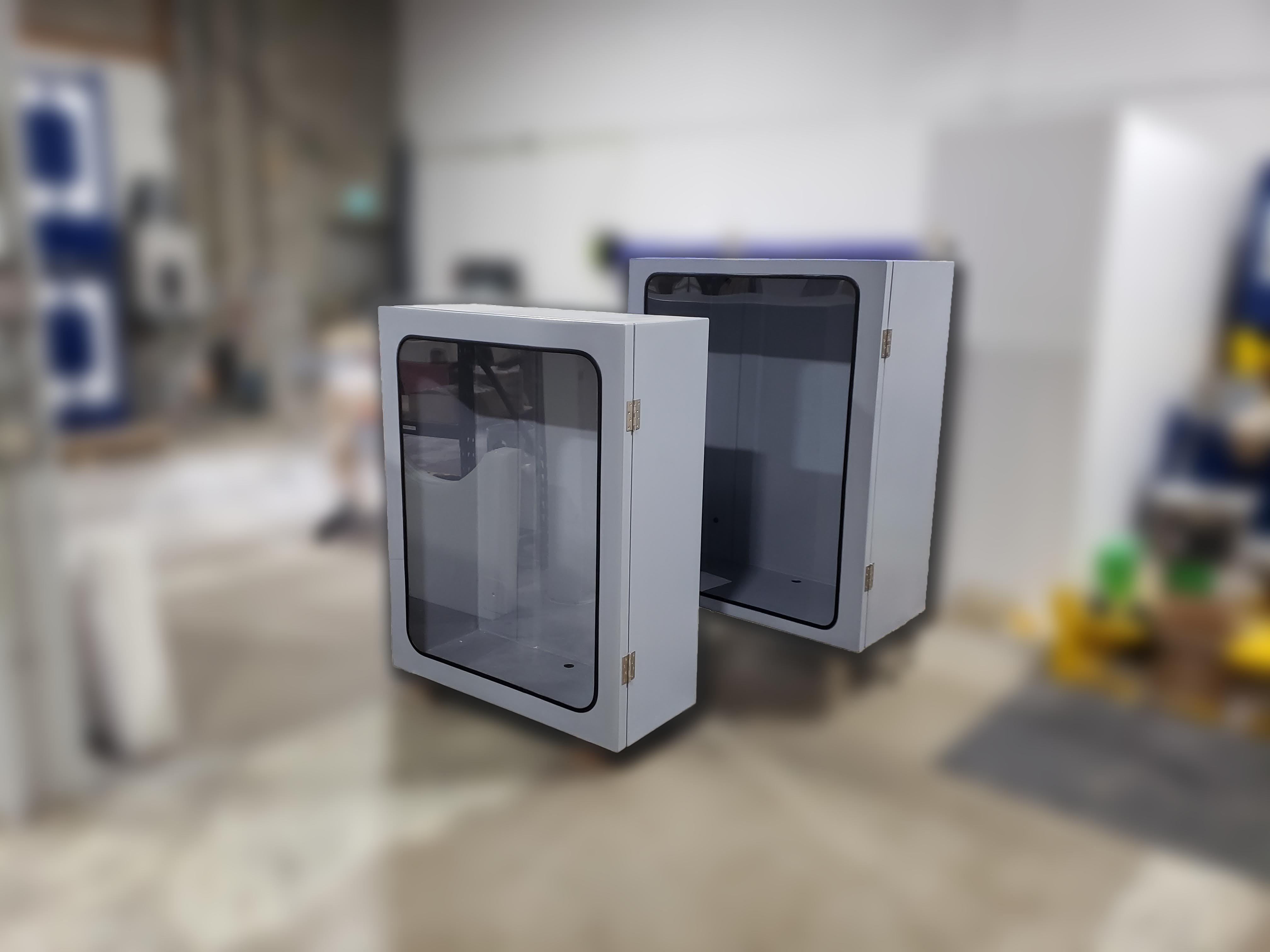

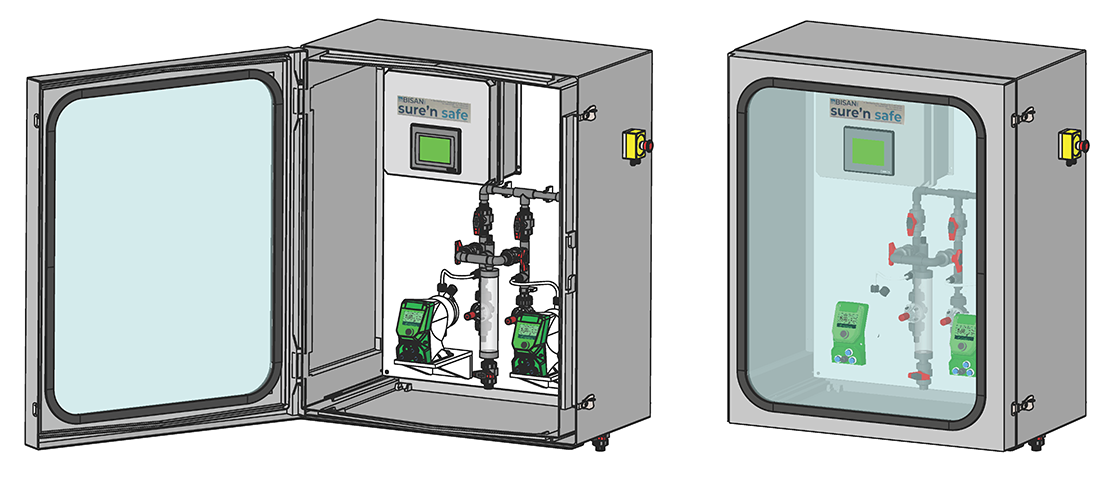

sure’n safe® Enclosure

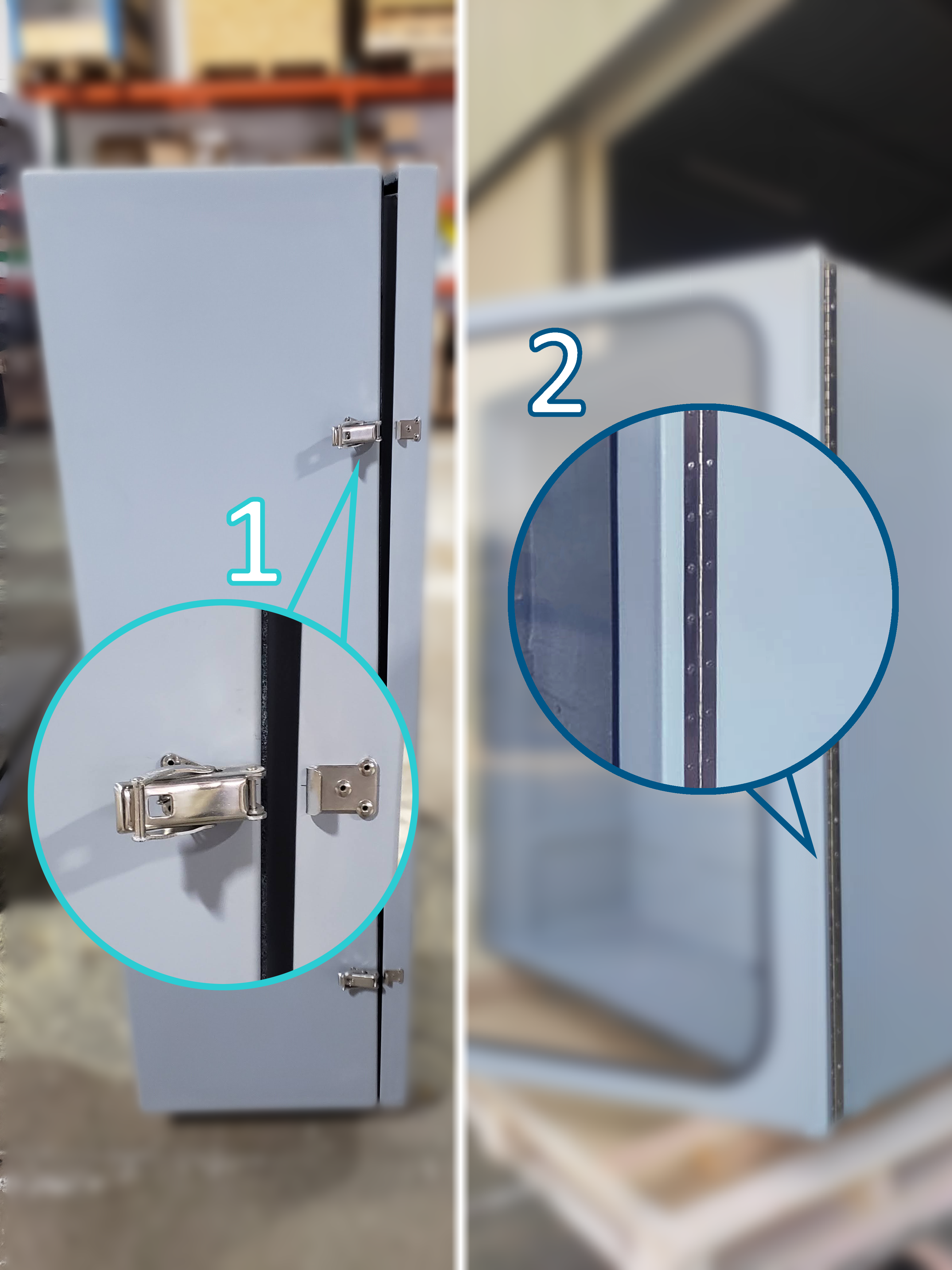

Latch and hinge

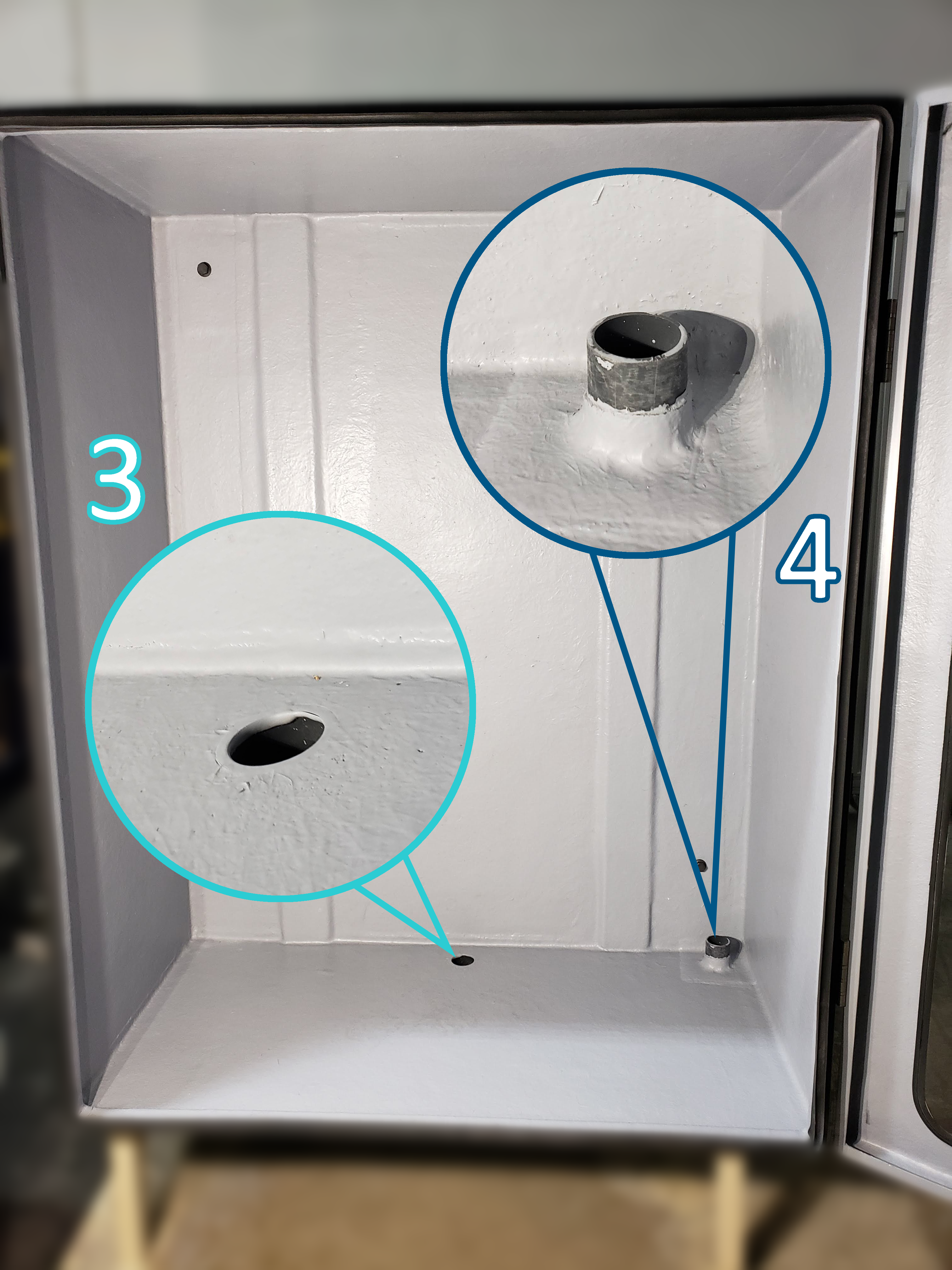

Sleeve and drain

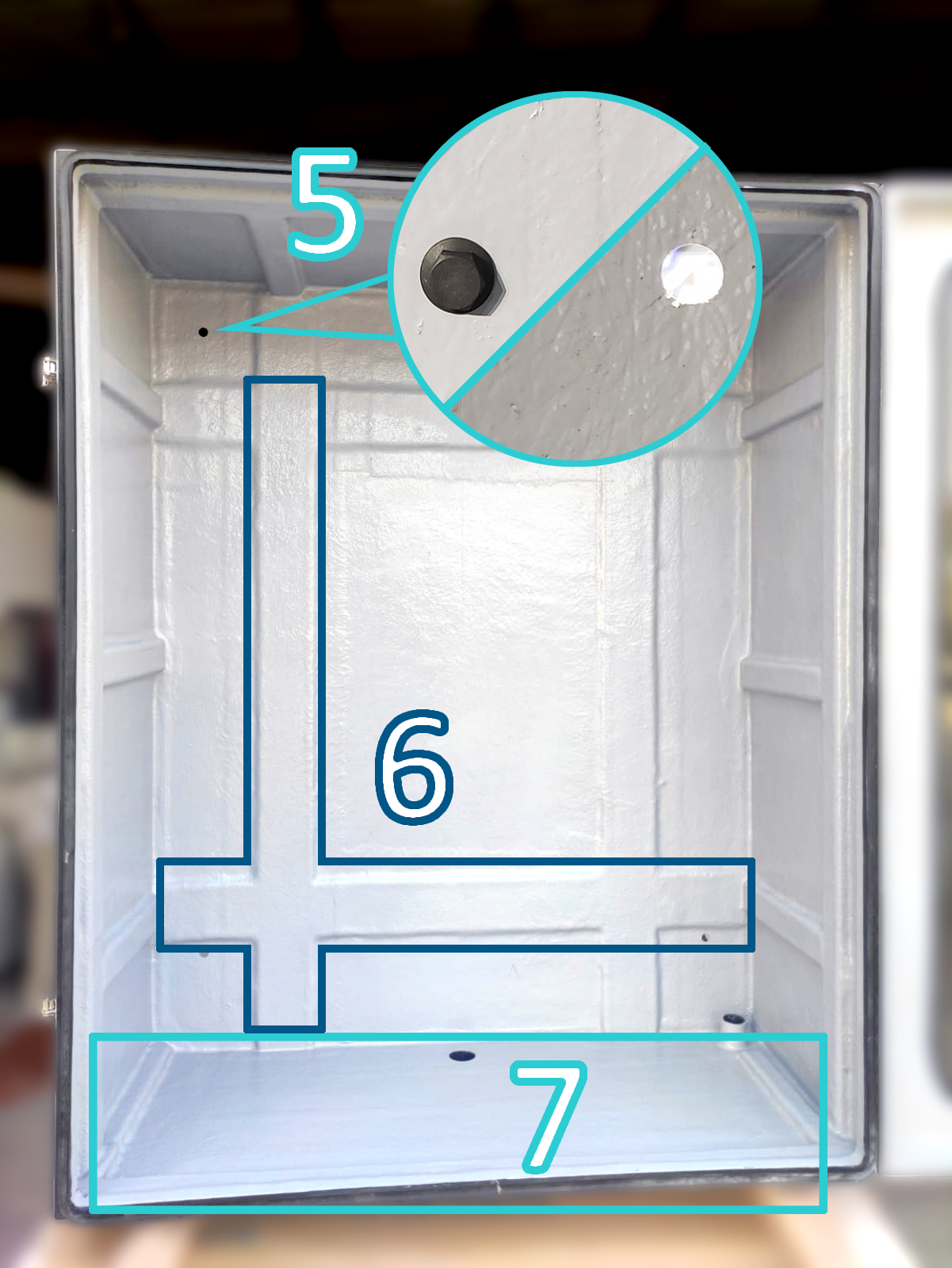

Stiffener plates and stiffener drain

- Specially designed to enclose chemical dosing systems for safe operation

- E-Stop push button installed outside of enclosure for safe stop of pumping when a chemical leak is observed

- Made with fiberglass material with clear acrylic window

Additionally, the enclosure is made of:

- Stainless steel quick disconnect latch

- Continuous stainless steel door hinge

- Hermetically sealed drain

- Hermetically sealed sleeve

- Pre-drilled and embedded stiffener plates for wall brackets

- Structural stiffeners

- Deep drain pan

sure’n safe® Chemical Dosing System

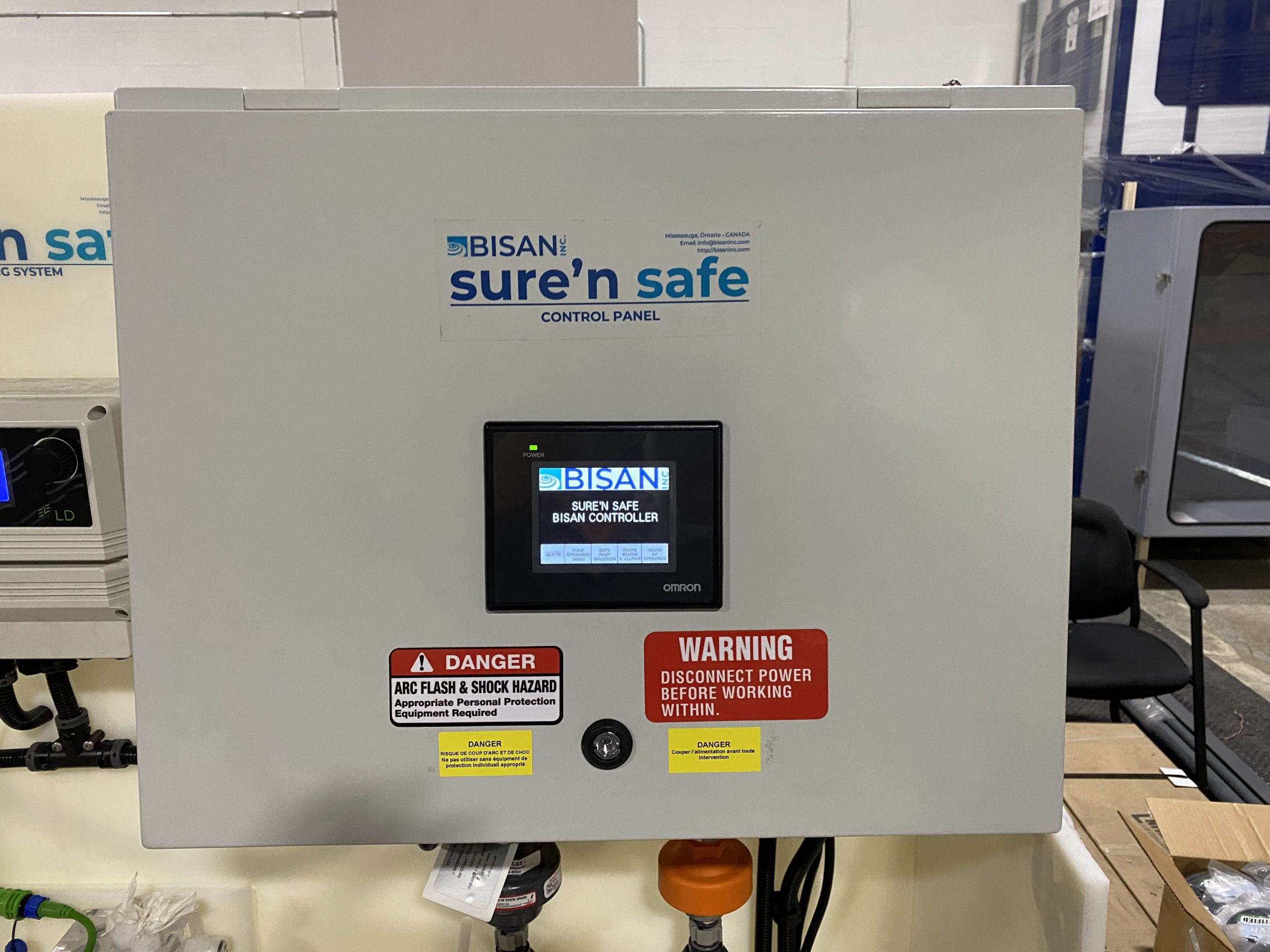

sure’n safe® Control Panel

Control Panel

Close-up

- HMI/PLC based control panel to ensure automatic switchover to standby pump if duty pump fails

- Safe operation by displaying alarms for tank low level and enclosure leak detection.

Additionally, Duty and Standby capability with the following features:

- Hand/Off/Auto Selection

- Duty Pump Selection

- Alternating Duty Pump, based on/off command or based on timer

- Pump Alarms

- Tank Low Level Alarm

- Leak Detection Alarm

- 4-20 mA output proportional with chemical usage

sure’n safe® Prisma Pump Features

PRISMA stepper motor-driven dosing pump has been designed by EMEC to be the best solution for offering high-accuracy metering and extreme reliability.

Thanks to the stepper motor and to the Multi-Function software, PRISMA dosing pumps offer complete control over dosing speeds and working modes as well as great flexibility, meeting even extremely complex application needs.

PRISMA can be programmed to work according the following working modes: Constant, Constant with external input, ppm, %, mlq, Pause-work, Weekly, mA, Pulse, Volt, external Batch, and manual Batch.

Slow Mode

Enabling Slow Mode, it is possible to reduce the suction speed of PRISMA from 100 to 1% of the normal speed, making it easier and more reliable the priming and the dosing even when the system has to work with particularly viscous liquids.

5 Year Warranty

Precisely for this reason, EMEC series of controllers, just as all the EMEC dosing pumps, are the only ones worldwide in the sector to be guaranteed for 5 years.